Excerpts from Modern Machine Shop – May Issue Feature Story-by Derek Korn

Alpha Manufacturing & Design were largely driven by specific new jobs it won. Ben Garden, who launched the Warsaw, Indiana, shop in 2008, started with a couple VMCs, anticipating his startup company would encounter a good deal of milling work from its first customer. The situation was similar when the shop added wire EDM and a Swiss-type lathe. Today, Alpha has 18 CNC machines, counting additional VMC, Swiss-type and EDM capacity (including sinker EDM) as well as a gun-drilling machine.

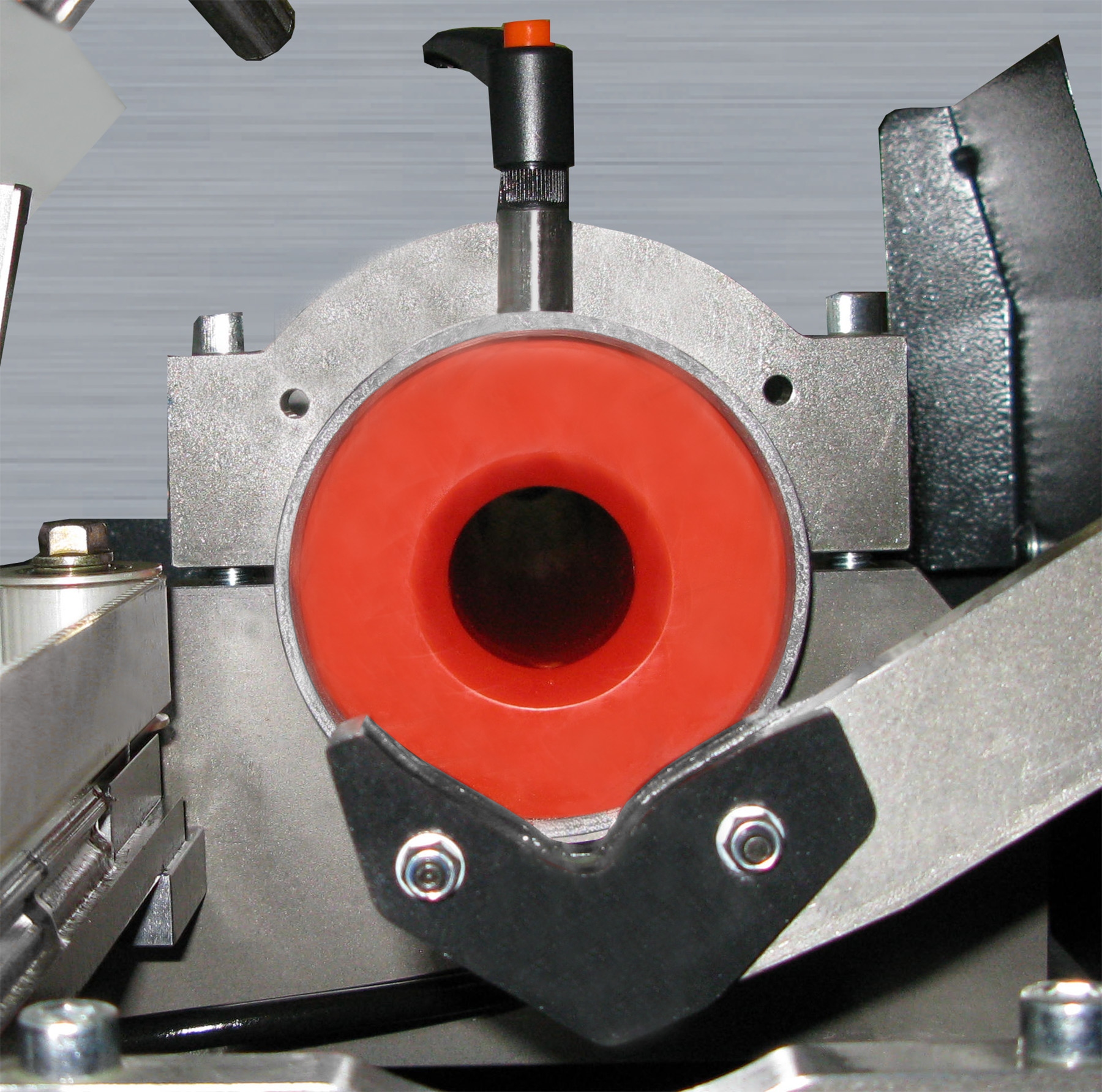

Conversely, its most recent machine addition, the shop’s most significant investment to date, represents a departure of sorts from the job-driven approach to equipment selection. In short, its new multitasking turn-mill was added to machine parts that primarily require milling work complete from bar stock, as opposed to the shop’s previous method of starting with blanks and running them across multiple pieces of equipment.

Alpha Manufacturing & Design uses its turn-mill to machine medical device components such as this chisel complete.

This 17-4 stainless steel part previously took one hour and 45 minutes to complete and ran across four machines. The turn-mill with B-axis milling spindle now machines it complete from rectangular bar stock in 35 minutes.